Coalescing Oil/Water Separators

Coalescing plate separators (CPS) by Rainwater Management are high efficiency oil removal systems that utilize polypropylene coalescing media. These systems should be installed on sites where a specific oil removal design is required or for sites where oil is the pollutant of concern. Suitable sites include gas stations, industrial loading facilities, automotive maintenance facilities, or any other site that has the potential for oil contamination.

Typical baffle box or oil/grit separators only provide gravity separation of free-standing oil where the droplet sizes are usually 150 microns and larger. The polypropylene coalescing media utilized in Rainwater Management’s systems is highly selective to hydrocarbons. It is a material used in oil booms to remove large amounts of oil in bodies of water. The media packs are constructed with thinly spaced polypropylene plates which provide maximum surface area to remove oil. The efficiency of Rainwater Management’s coalescing plate separators can achieve hydrocarbon effluent concentrations of 10–15 mg/l for oil droplet sizes 50 microns or lower.

All oil droplets naturally rise with a long enough residence time. The smaller oil droplets need the enhanced effect of the coalescing media to allow for removal as the rise velocity is much slower. As flow passes through the polypropylene coalescing media, the hydrocarbon droplets accumulate on the surface of the thinly spaced media to combine together (coalesce) until they are buoyant enough to float to the water surface in the unit.

Coalescing plate separators by Rainwater Management are available in typical precast concrete vault structures and small diameter precast manhole structures. These small diameter manhole structures are ideal for smaller site applications and offer a lower cost of supply and installation.

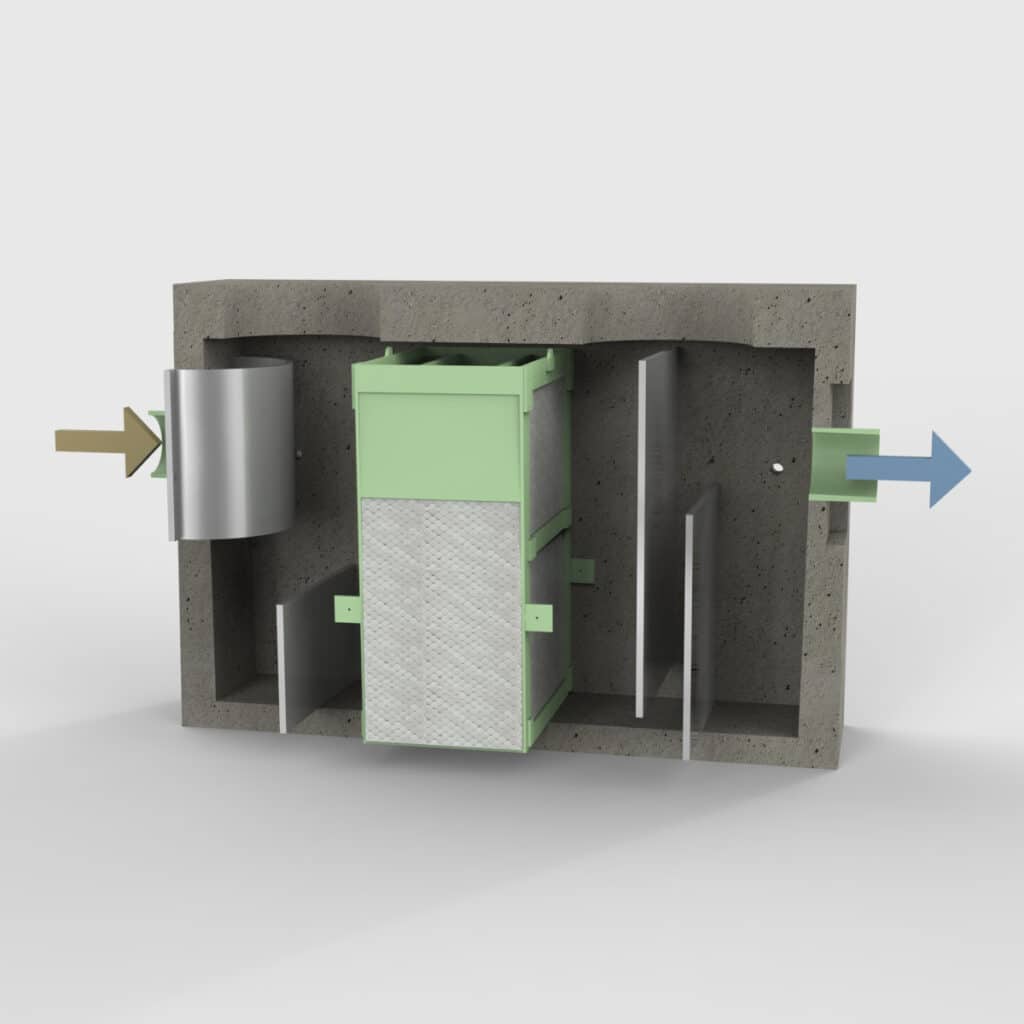

The flow through these systems is laminar. The influent enters the system and must pass over or through an inlet baffle which allows for coarser sediment to settle. The larger oil droplets naturally rise with a long enough residence time. The smaller oil droplets need the enhanced effect of the coalescing media to allow for removal. As flow passes through the polypropylene coalescing media, small hydrocarbon droplets accumulate on the many surfaces of the thinly spaced media to combine together (coalesce) until they are buoyant enough to float to the water surface in the unit. This occurs through the numerous channels running vertically throughout the media. The treated water must flow up a T-pipe or past an outlet baffle leaving behind all the suspended oily pollutants.

The ideal system design minimizes the sediment that will reach the Coalescing Separator. For sites with oil and sediment we recommend a RWM SS or RWM Diskman to pre-treat and remove the sediment/trash that may be present. The plates have weep holes in the bottom of the corrugations that allow for any sediment that may settle in the plates to sink to the bottom of the chamber. This helps minimize the need for cleaning the plates.

Maintenance is performed by pressure washing the media packs inside the unit. Most maintenance can be performed with the plates in place by placing a cleaning wand down through the plates. The removal of the plates for cleaning can be done but is a less desirable and more labour intensive method. A standard vacuum truck is utilized to clean out the unit with the oil dealt with according to local regulations.